In 1949, Hans J. Wegner began working on what would become one of his most iconic creations, the Wishbone chair. He moved to Denmark’s Funen Island, staying in the family home of Holger Hansen, then-CEO of furniture manufacturer Carl Hansen & Søn. Working alongside the company’s craftsmen, he devised a streamlined chair with a Y-shaped back and handwoven seat.

The piece, which Wegner called CH24, has been in continuous production since 1950 and is still made on Funen Island using the same 14 components and 100 processes employed by Wegner.

Wegner began his career as a cabinetmaker, apprenticed to master craftsman H.F. Stahlberg at 14 years old and later attended Copenhagen’s School of Arts and Crafts. He transitioned to furniture design in the 1940s and, in 1944, began to develop seating based on Ming dynasty chairs.

Inspired by portraits he saw of Danish merchants sitting on these chairs, he combined a graceful East Asian design aesthetic with current modernist principles.

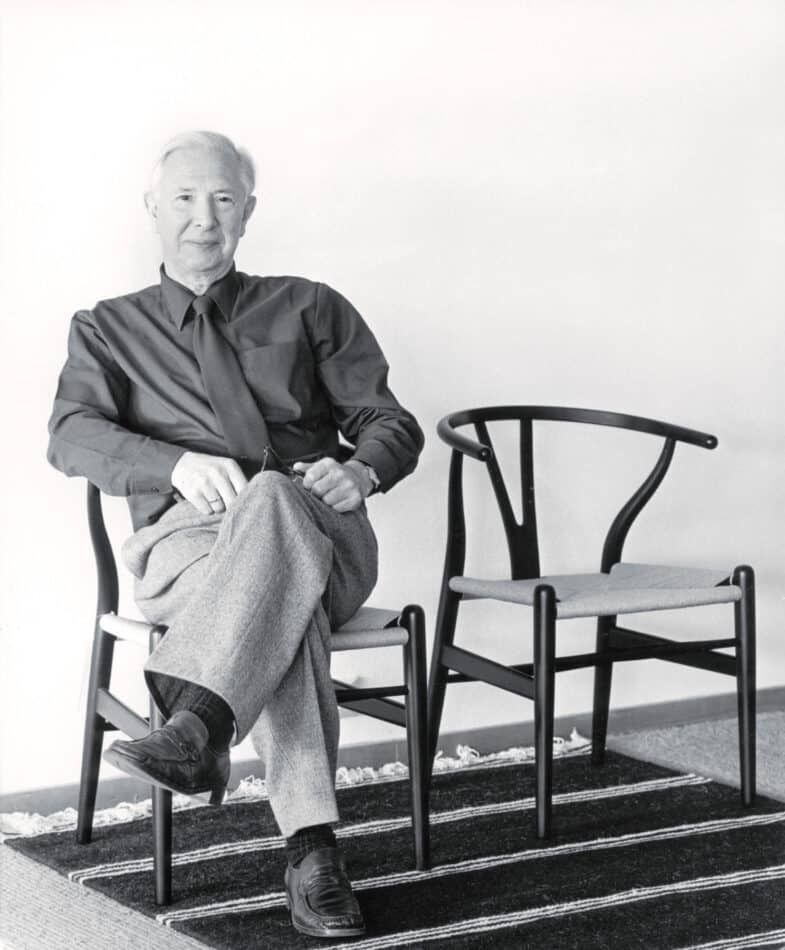

Over his lifetime, Wegner designed nearly 500 chairs, so it’s no wonder Carl Hansen & Søn refers to him as “the Master of the Chair.” The 112-year-old company, still family owned, is now run by Carl Hansen’s grandson, Knud Erik Hansen.

Hansen has kept up the company tradition of celebrating the dual birthdays of the Wishbone chair and Hans J. Wegner himself by releasing limited-edition designs.

For this year’s 70th anniversary of the chair, the company collaborated with London-based designer Ilse Crawford. The resulting piece has a sleek navy-blue frame finished with a water-based high-gloss lacquer. “The color is inspired by Wegner’s long-standing fascination with Asian design history and craft. It’s a collector’s piece — one that will last for generations,” says Hansen.

To learn more about the famed Wishbone, we spoke with Hansen about craftsmanship, process and what you might find on the underside of the chair.

“Timeless beauty, comfort, craftsmanship and sustainability” are core values at Carl Hansen & Søn. How are they embodied in the Wishbone chair?

The Wishbone chair’s quiet, elegant look and simple form make it a timeless classic. The intense working relationship between Hans J. Wegner and Carl Hansen & Søn’s craftsmen while the chair was being developed in 1950 ensured harmony between craftsmanship and comfort. And the Wishbone chair is innately sustainable and gentle toward nature, as it’s made strictly from wood and paper cord.

In 1950, the Wishbone chair took three weeks to make, entirely by hand. What elements of the production remain the same 70 years later?

To this day, most of the nearly 100 processes involved in creating the Wishbone chair are done by hand, as they have been ever since Wegner worked with Carl Hansen & Søn craftsmen.

Today, it is only in the initial production phase that we use machines. The grinding into the wood and forming of the various parts are all done by modern machinery. The machinery work replaces the heavy operations that previously wore down the craftsmen forming and crafting the wood.

How long does it take to make a Wishbone chair?

Craftsmen spend several weeks assembling the wooden parts and sanding and treating the wood. The unique seat is handwoven from paper cord by expert weavers, who take about an hour to produce one. Altogether, the process takes approximately three weeks.

Wegner developed the Wishbone on Denmark’s Funen Island. Are the chairs still made locally?

At first, the chairs were made in Odense [on Funen Island]. In 2003, Carl Hansen & Søn moved to a brand-new factory in Aarup, also on the island. And in 2017, we moved to the present factory, in Gelsted — also on the Danish island of Funen!

Where do you use the Wishbone chair in your own interiors?

Both in the office and at home. The Wishbone chair is special and fits into nearly every environment. I live in a house from 1670, and it fits perfectly into the dining room as well as the lounge rooms. The chair has a shape that fits into all spaces.

What do most people not know about the Wishbone?

Today, the waste from the production of the Wishbone chair is used to heat more than 450 houses in the town adjacent to our factory in Gelsted. Also, very often you will find initials written underneath the chairs in pencil by the carpenter. He writes his initials to send a small message to wish both the chair and its new owner, “Good Luck for the Future”!