Flooring

Early 19th Century Dutch Antique Flooring

Stone, Marble, Belgian Black Marble, Carrara Marble

Mid-19th Century French Antique Flooring

Terracotta

Late 18th Century French Antique Flooring

Terracotta

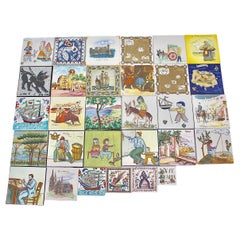

Late 20th Century Mid-Century Modern Flooring

Ceramic

18th Century French Antique Flooring

Terracotta

Late 18th Century Dutch Antique Flooring

Marble, Carrara Marble

16th Century French Antique Flooring

Terracotta

Late 18th Century French Antique Flooring

Terracotta

18th Century French Antique Flooring

Terracotta

Early 1900s Italian Antique Flooring

Marble

Early 19th Century French Antique Flooring

Terracotta

21st Century and Contemporary Moroccan Flooring

Silk

Late 18th Century French Antique Flooring

Terracotta

1870s Dutch Antique Flooring

Carrara Marble

Mid-17th Century French Rustic Antique Flooring

Limestone

19th Century French Antique Flooring

Limestone

17th Century Spanish Rustic Antique Flooring

Limestone

1810s European Antique Flooring

Reclaimed Wood

1920s Italian Neoclassical Vintage Flooring

Carrara Marble

1880s Italian Classical Greek Antique Flooring

Carrara Marble

Early 17th Century Italian Antique Flooring

Limestone

21st Century and Contemporary Vietnamese Modern Flooring

Cement

19th Century American Victorian Antique Flooring

Wood

21st Century and Contemporary Moroccan Flooring

Marble

21st Century and Contemporary Moroccan Flooring

Silk

21st Century and Contemporary European Flooring

Limestone

Mid-19th Century Dutch Antique Flooring

Marble, Carrara Marble

20th Century Flooring

Cement

Early 1900s Italian Antique Flooring

Marble

Mid-18th Century French Antique Flooring

Terracotta

20th Century Spanish Flooring

Cement

21st Century and Contemporary Italian Modern Flooring

Marble

21st Century and Contemporary Moroccan Flooring

Silk

19th Century Antique Flooring

Cement

20th Century Flooring

Cement

Late 19th Century Antique Flooring

Cement

Mid-19th Century English Victorian Antique Flooring

Clay

Late 19th Century Antique Flooring

Cement

21st Century and Contemporary Moroccan Flooring

Silk

21st Century and Contemporary Italian Modern Flooring

Marble

Early 20th Century Flooring

Cement

Early 1900s Italian Antique Flooring

Marble

Early 17th Century Italian Rustic Antique Flooring

Limestone

21st Century and Contemporary Italian Modern Flooring

Marble

19th Century French Antique Flooring

Terracotta

2010s African Flooring

Terracotta

21st Century and Contemporary Italian Modern Flooring

Marble

18th Century Dutch Antique Flooring

Carrara Marble

Mid-20th Century European Mid-Century Modern Flooring

Limestone, Marble, Carrara Marble

Late 18th Century French Antique Flooring

Marble, Carrara Marble

21st Century and Contemporary Italian Modern Flooring

Marble

21st Century and Contemporary Italian Modern Flooring

Marble

15th Century and Earlier English Antique Flooring

Stoneware

19th Century French Antique Flooring

Terracotta

Early 20th Century English Arts and Crafts Flooring

Clay

Late 19th Century English Victorian Antique Flooring

Clay

Early 20th Century Spanish Arts and Crafts Flooring

Cement

Late 18th Century French Antique Flooring

Terracotta

21st Century and Contemporary Italian Modern Flooring

Marble

Late 20th Century French Belle Époque Flooring

Ceramic

Antique, New and Vintage Flooring

Carefully chosen antique, new and vintage flooring, while not usually considered a focal point, can play a huge role in designing how a space should look and feel.

Archaeologists have identified glazed brick tiles and polished stones on historic floors and other surfaces around the world. Some of the earliest known glazed bricks date to a 12th-century B.C. facade in Susa, in today’s Iran.

Whether you choose wide planks to contrast with your modern appliances in your farmhouse-style space or understated oak for a clean contemporary look, humble wood can play a starring role when it comes to flooring. Alternately, vintage tiles can be the “it” factor in your kitchen, bathroom, patio or bedroom. Gapless mosaics forming tessellations or complicated geometric patterns can provide a bold statement, and one doesn’t have to be polymath designer Gio Ponti, for example, to create dramatic floors with these tiles. (Ponti was arguably the most important figure in 20th-century Italian architecture and design, and diagonally patterned floors, meant to make rooms more dynamic, were a signature of his.)

Modern 21st-century flooring and new and made-to-order flooring come in many styles. However, choosing antique or vintage flooring or a unique pattern from innovative designers like Aimee Wilder can add an extra layer of charm and sophistication to an interior or other space.

On 1stDibs, find flooring to match a range of styles and tastes.